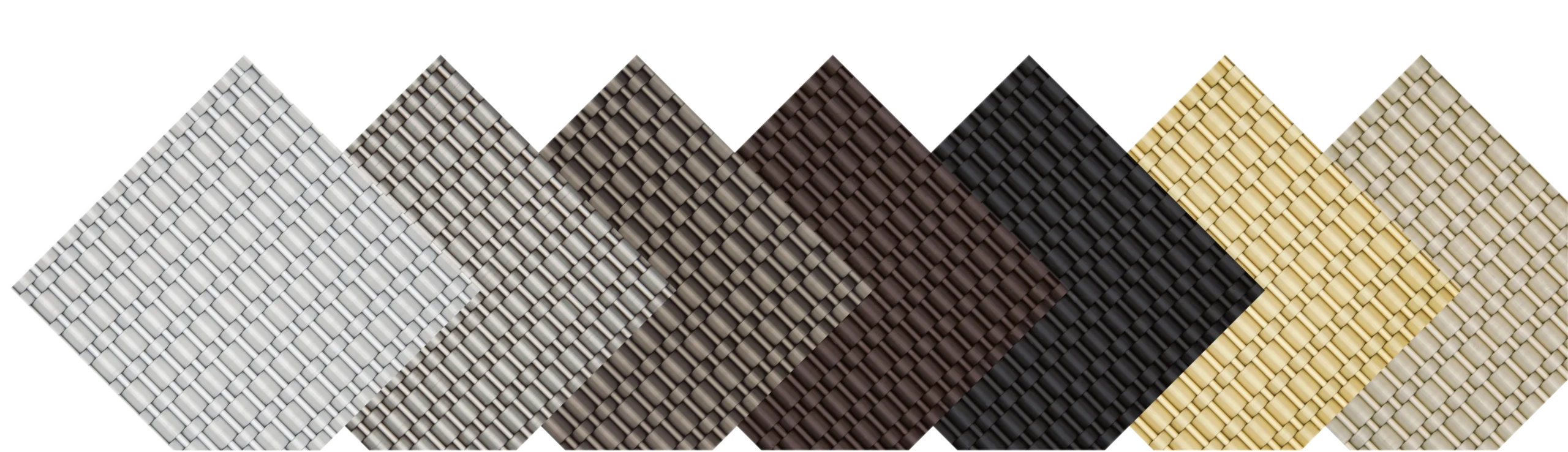

Wire Mesh Finishes

Natural Finish

These are the materials without any extra treatment.

- Stainless Steel: It can be used for interiors and exteriors. Its appearance is smooth and metallic gray.

- Aluminum: In its untreated state, aluminum exhibits a sleek and metallic appearance suitable for interior applications. The surface presents a smooth and silvery-gray finish, providing a contemporary and versatile aesthetic. It maintains its original appearance with minimal color changes.

- Copper or Brass: Wire starts out “shiny” but is considered “live.” This means that the copper/brass wire will be almost immediately susceptible to color changes from the handling and fabrication of the mesh. Codina cannot guarantee color consistency when it reaches its final installation point. Moreover, the color will continue to change at a unique rate and intensity depending on the environment and amount of handling. It can be used for interiors and exteriors.

Anodized

Anodizing is a surface treatment of aluminum that consists of the formation of a layer of aluminum oxide in a controlled way, in which a continuous current is passed through the surface of the aluminum. This process provides a high level of protection against corrosion and a high resistance to surface abrasion. The protection layer varies between 5-7μm for indoor/mild environments, about 15 μm for outdoor and harsher climates and up to 20/25μm for industrial, marine, and extreme environments. Another peculiarity of anodizing is that, thanks to the porous structure of this anodic layer, it allows us to obtain a wide range of coloration.

Powder Coated

Lacquered

Applying a transparent lacquer on the top surface will create a protective barrier and prevent the material from being marked or tarnished to the touch. This lacquer will flake off over time, but will slow down the natural process of the copper. The color changes in the material will not be as immediate as with the natural finish. We recommend this type of finish especially for indoor use, where the mesh will be exposed and within easy reach of handling.

Sandblasted

This process consists of the projection of abrasive particles on the stainless steel mesh. With this treatment, we change the natural appearance of the material itself. We go from a smooth metallic gray color, typical of stainless steel, to a darker, matte gray color and a textured finish. We will not have so much light reflection on the metal, and we will give a matte appearance on the entire mesh. It can be used for interiors and exteriors.