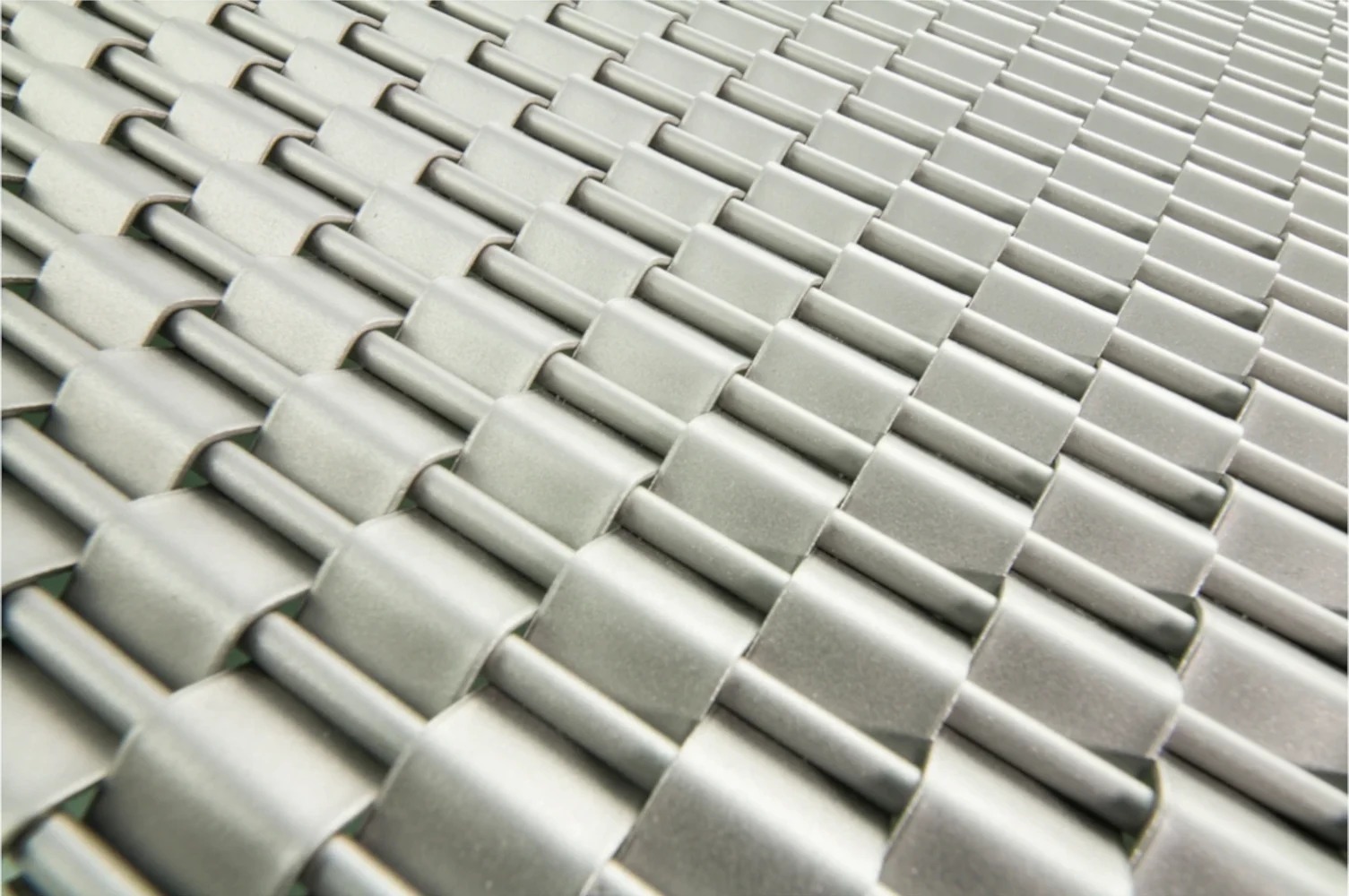

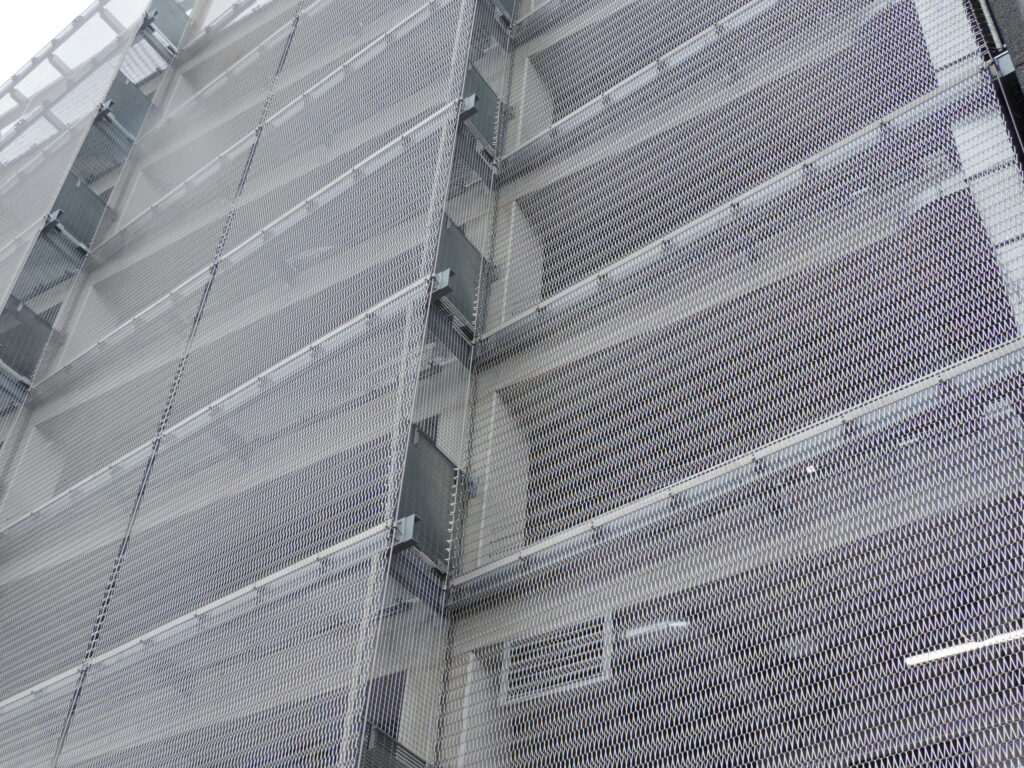

Stainless steel meshes are the most commonly used material for architectural projects. Thanks to their properties, they are ideal for exterior applications such as facades, enclosures, or cladding. They offer an excellent balance of properties, price, and aesthetics.

Stainless steel is a material widely used in industrial and architectural applications, due to its physical and structural properties. It has a high resistance to oxidation and corrosion due to the presence of chromium in its composition; This element combines with oxygen and creates a protective surface layer of chromium oxide, called passive layer.

It has high mechanical and wear resistance, high durability and is easy to machine and handle.

It is a material highlighted by its high sustainability, as it has a long service life and requires little or no maintenance. In addition, it is 100% recyclable at the end of its useful life, with an average recycling rate of between 60% and almost 90%. Its production generates minimal levels of CO2 and other emissions.

It has numerous applications in architecture and interior design: enclosure of pavilions or garages, rehabilitation of facades, elevators, stairs, floors, ceilings, protection of openings, division of spaces, etc.

Codina Architectural offers several finishes for this material.

Other materials and finishes available on request. Ask us!

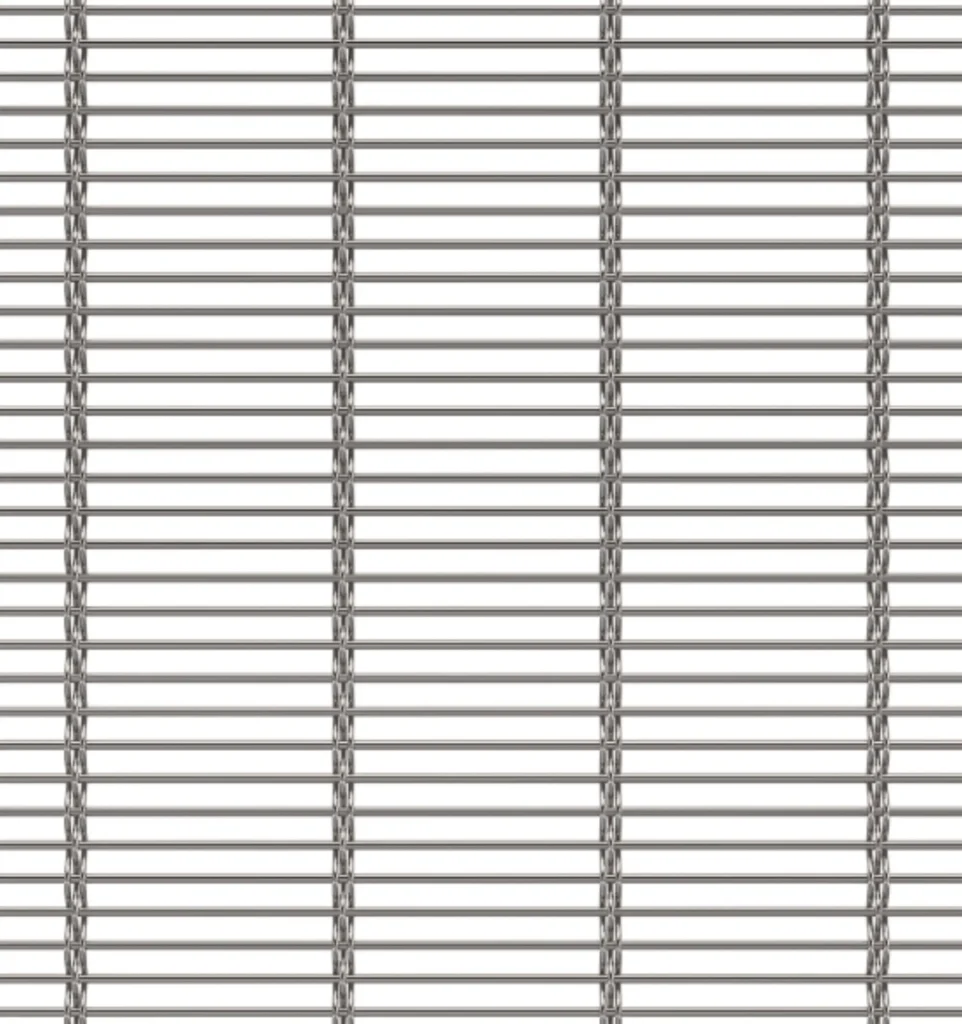

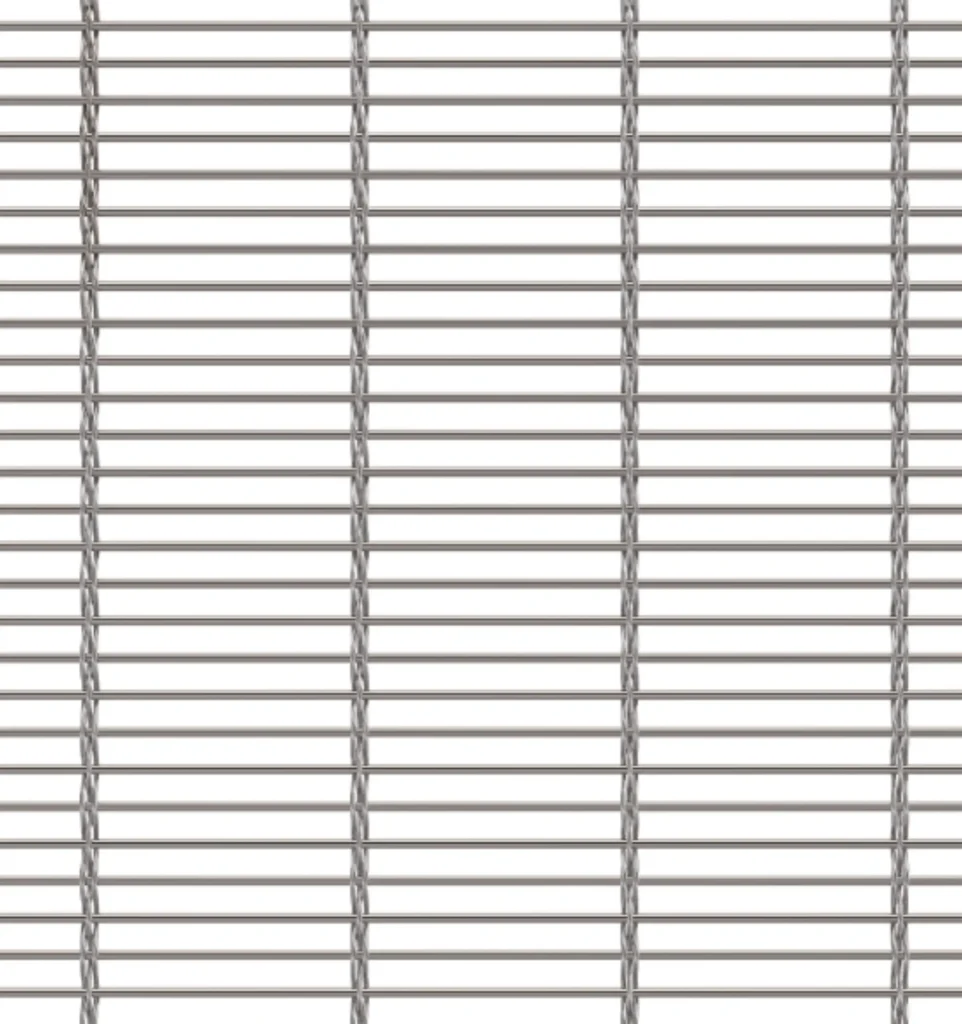

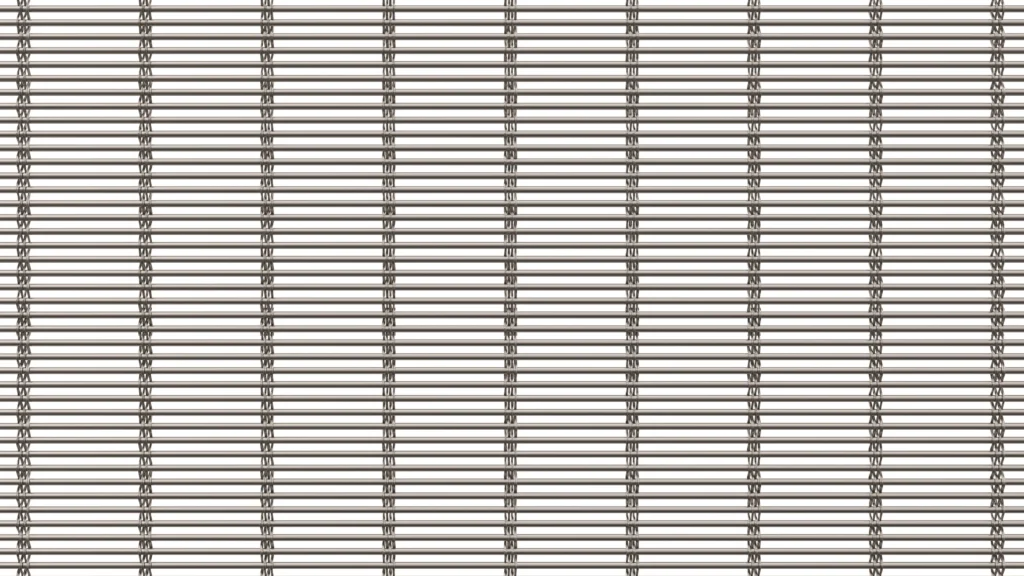

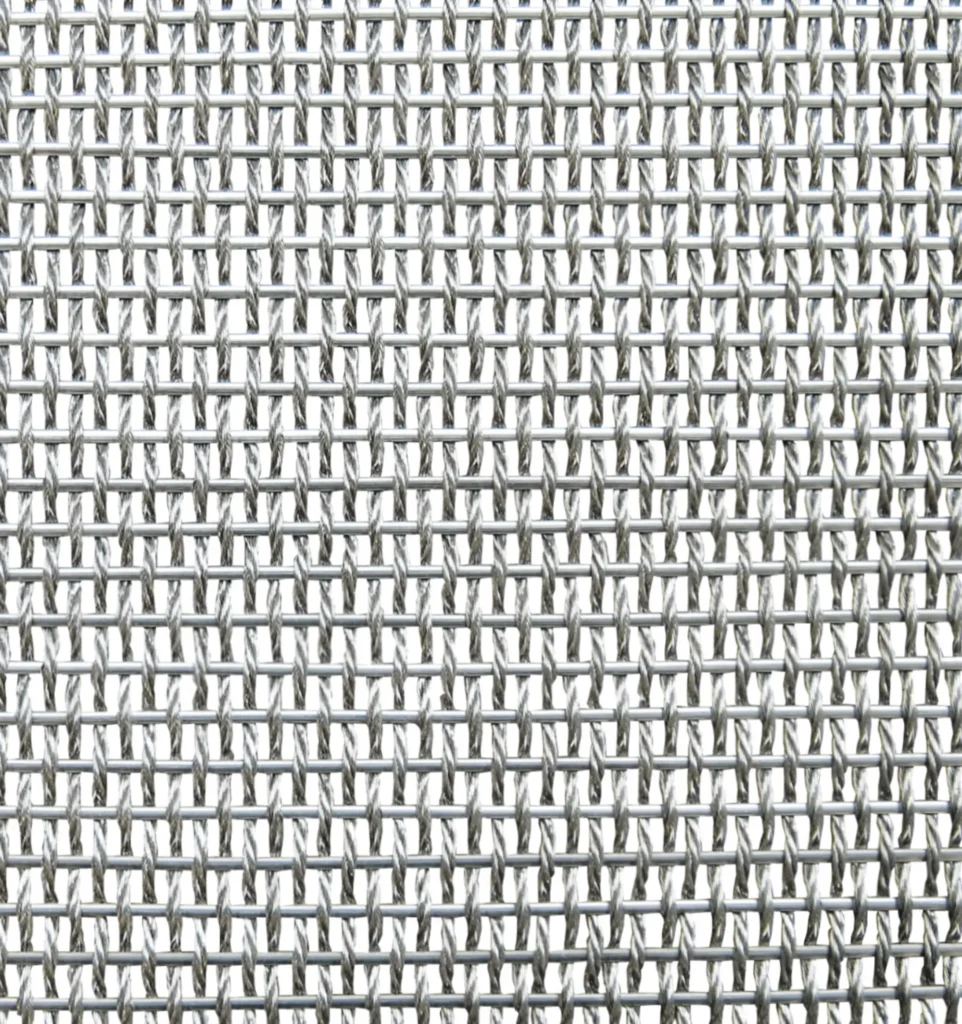

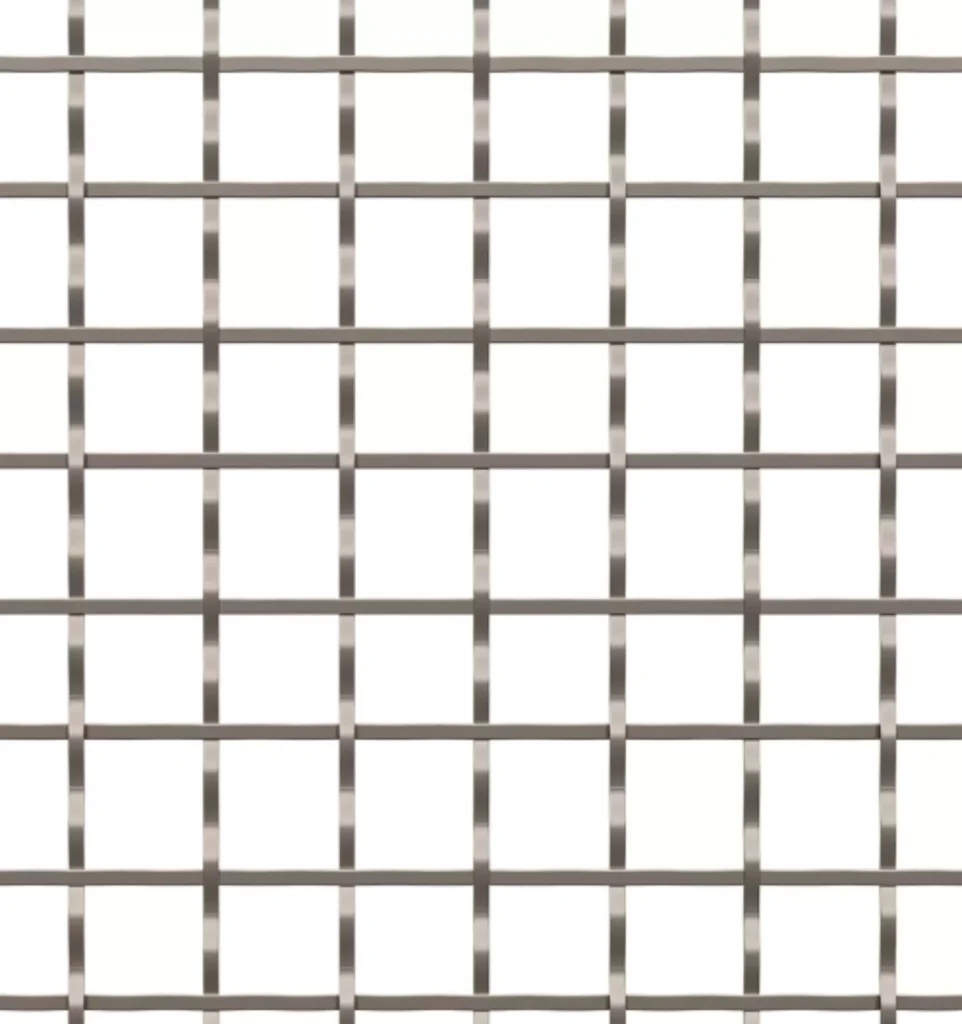

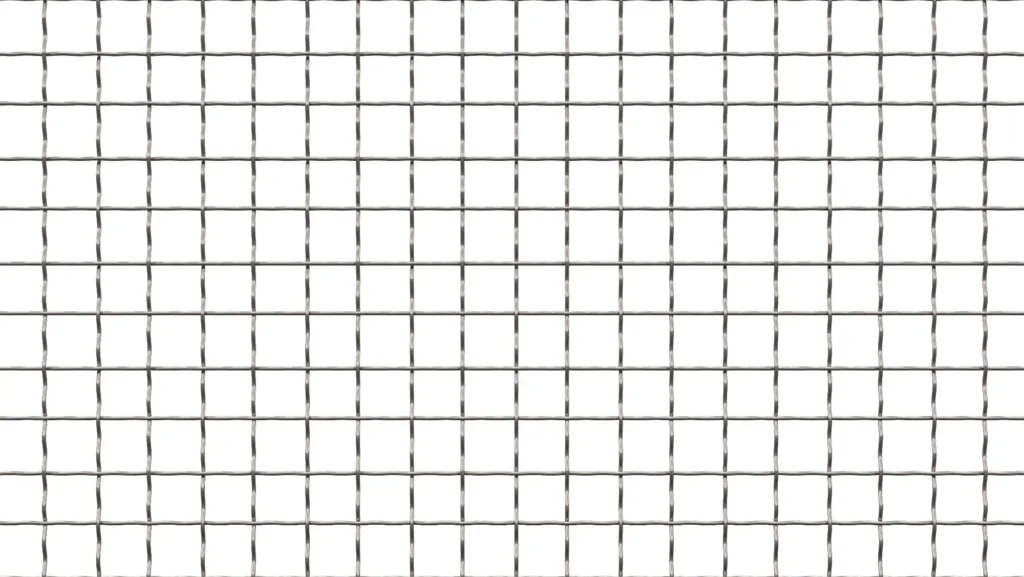

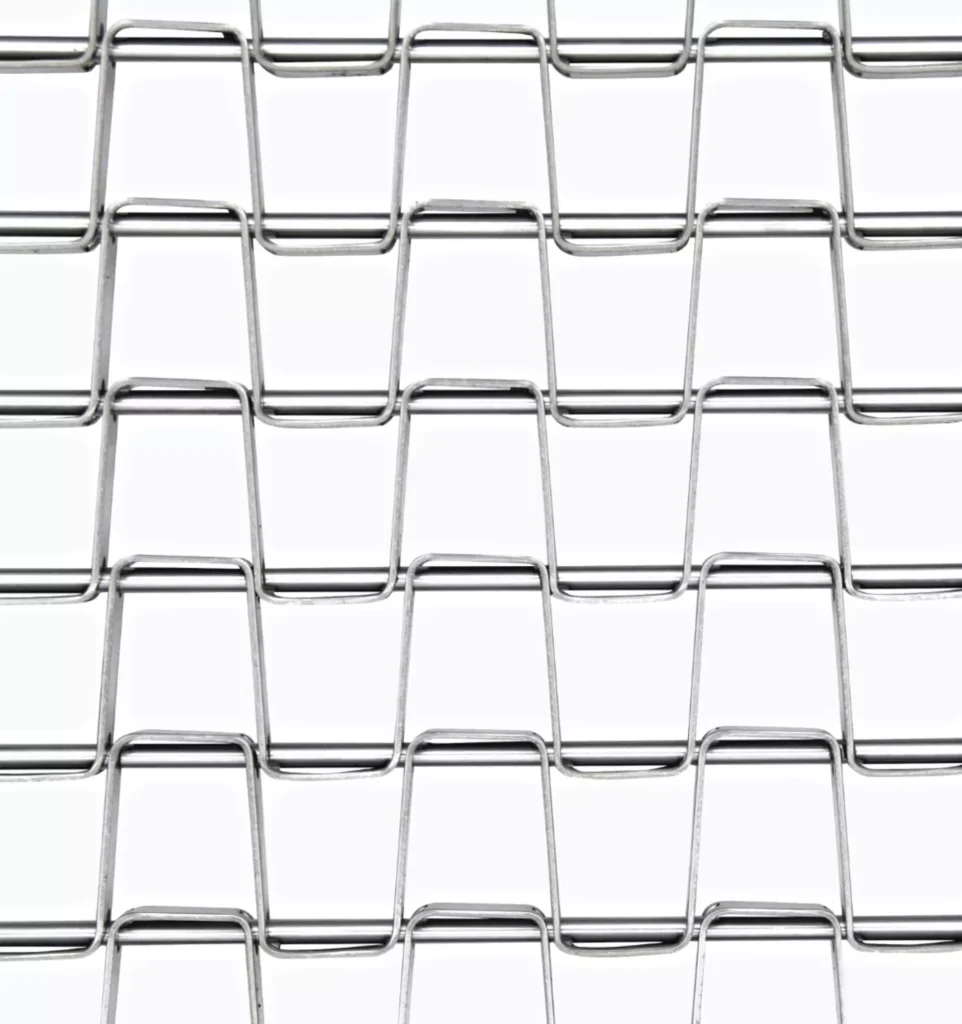

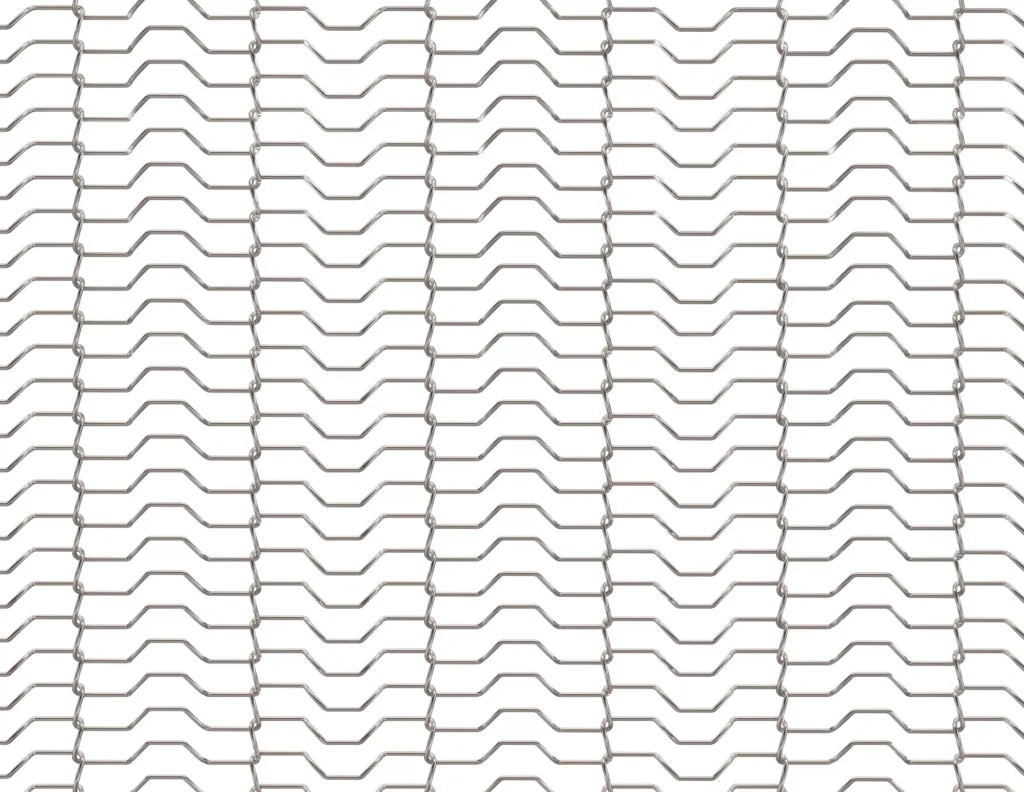

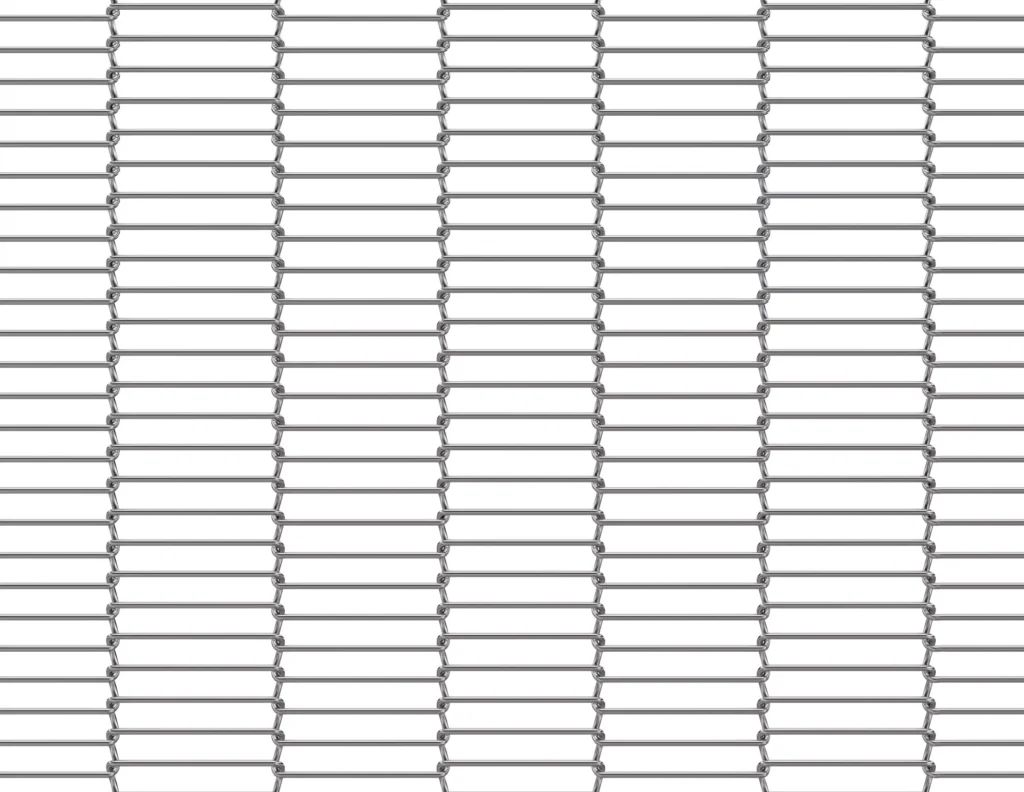

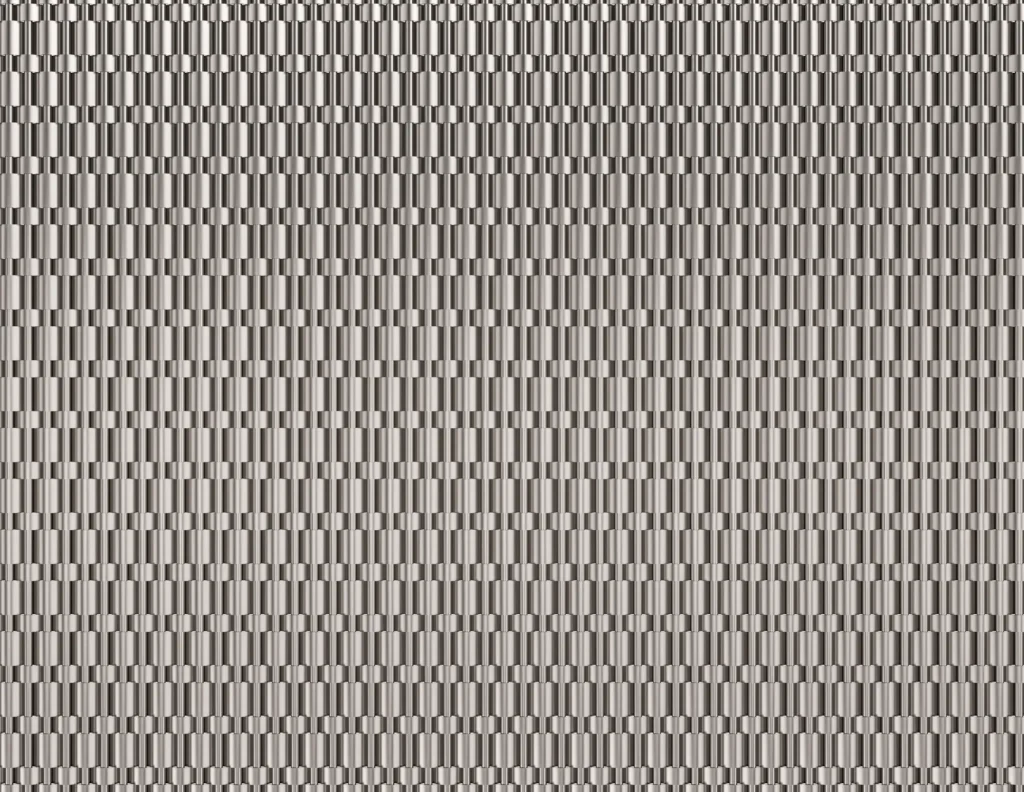

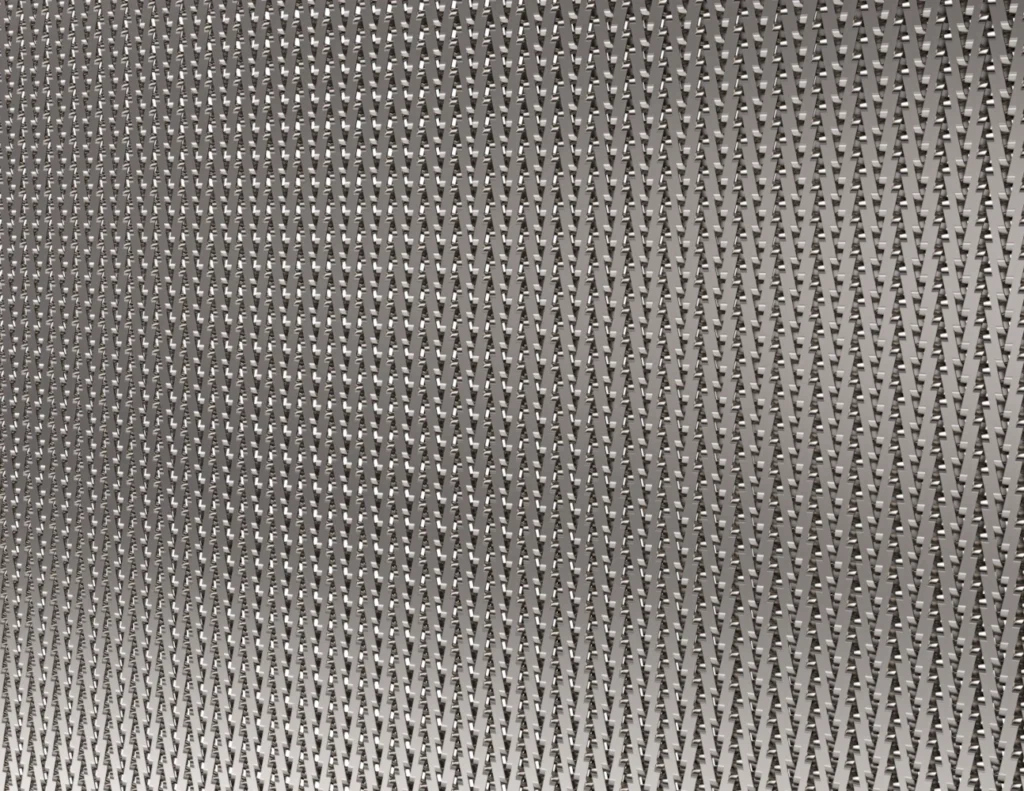

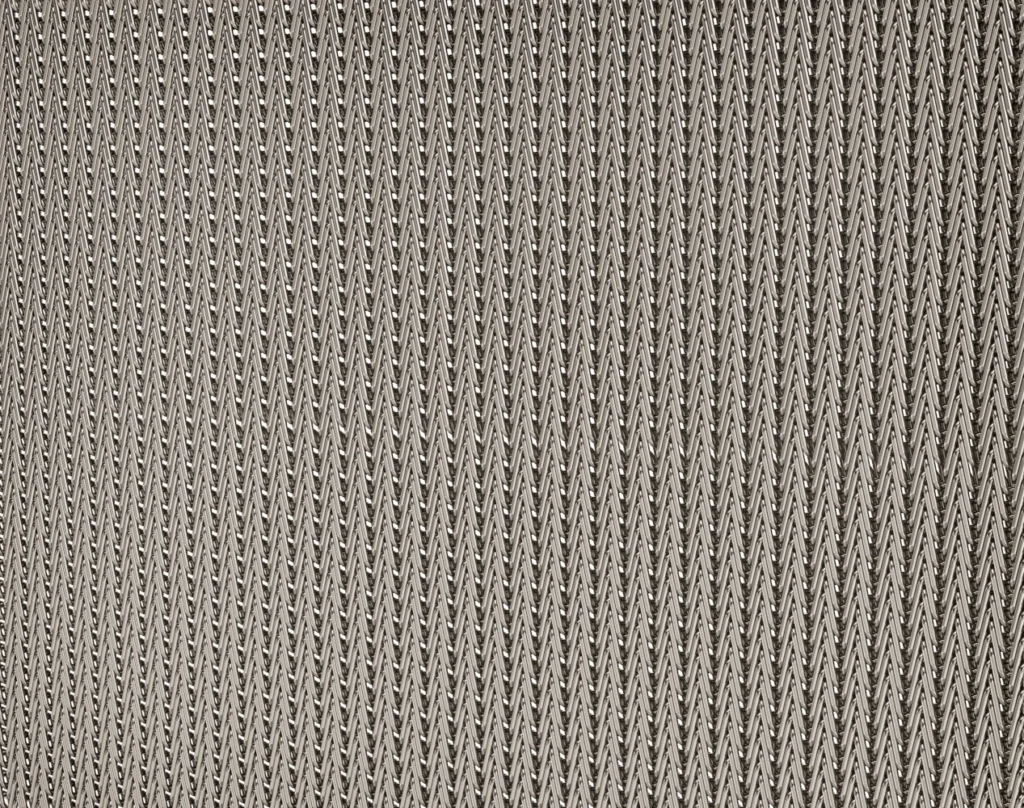

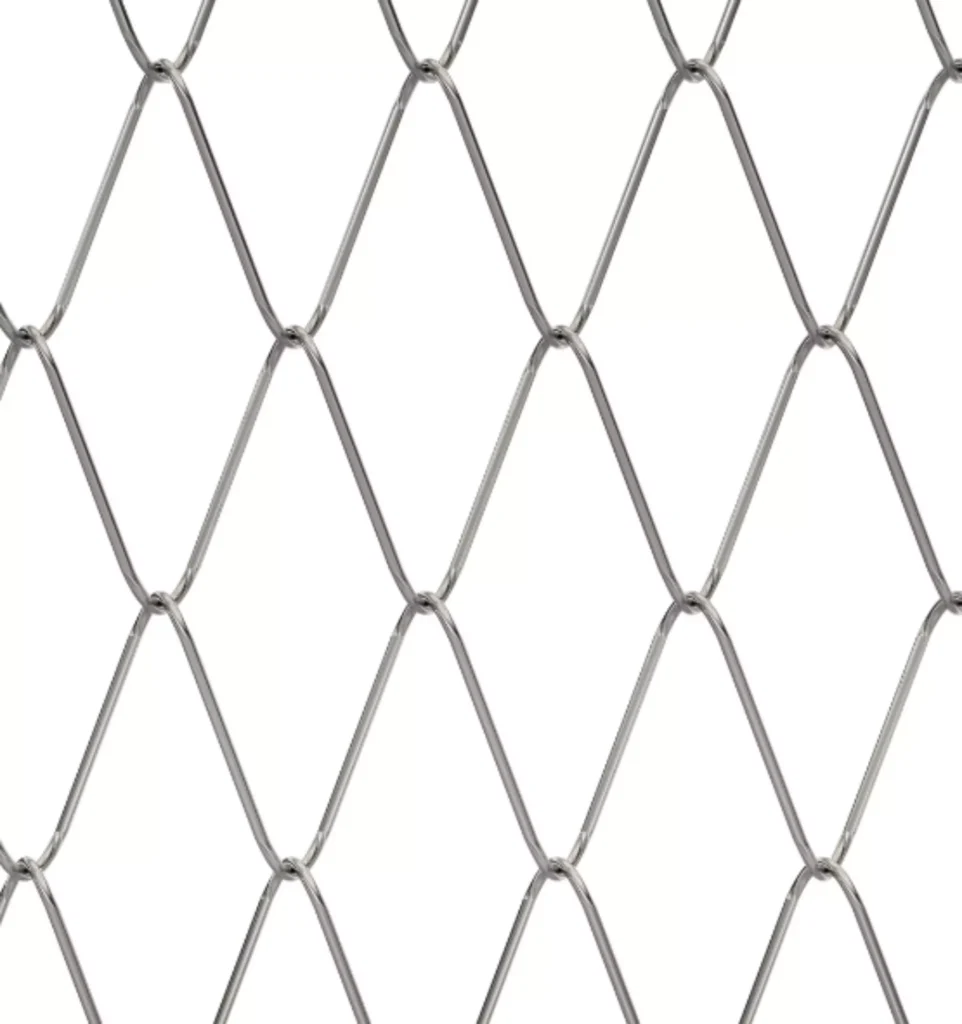

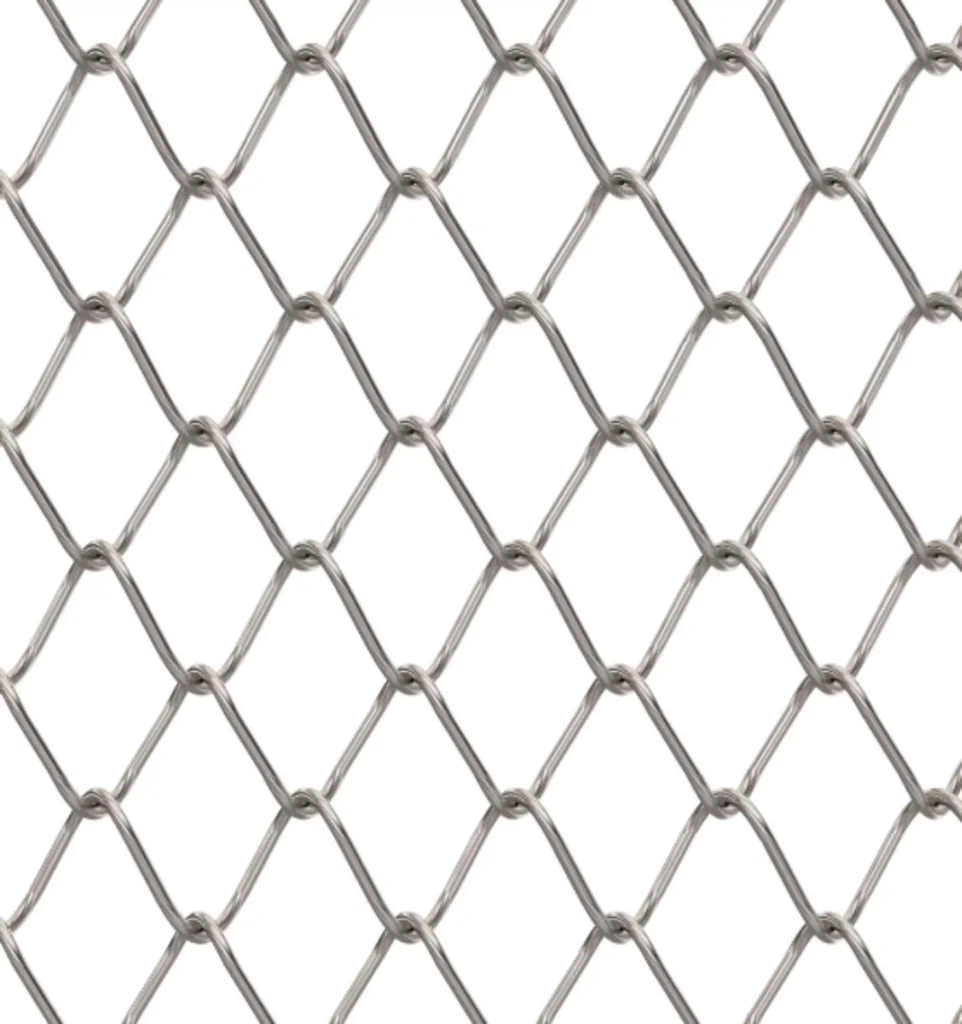

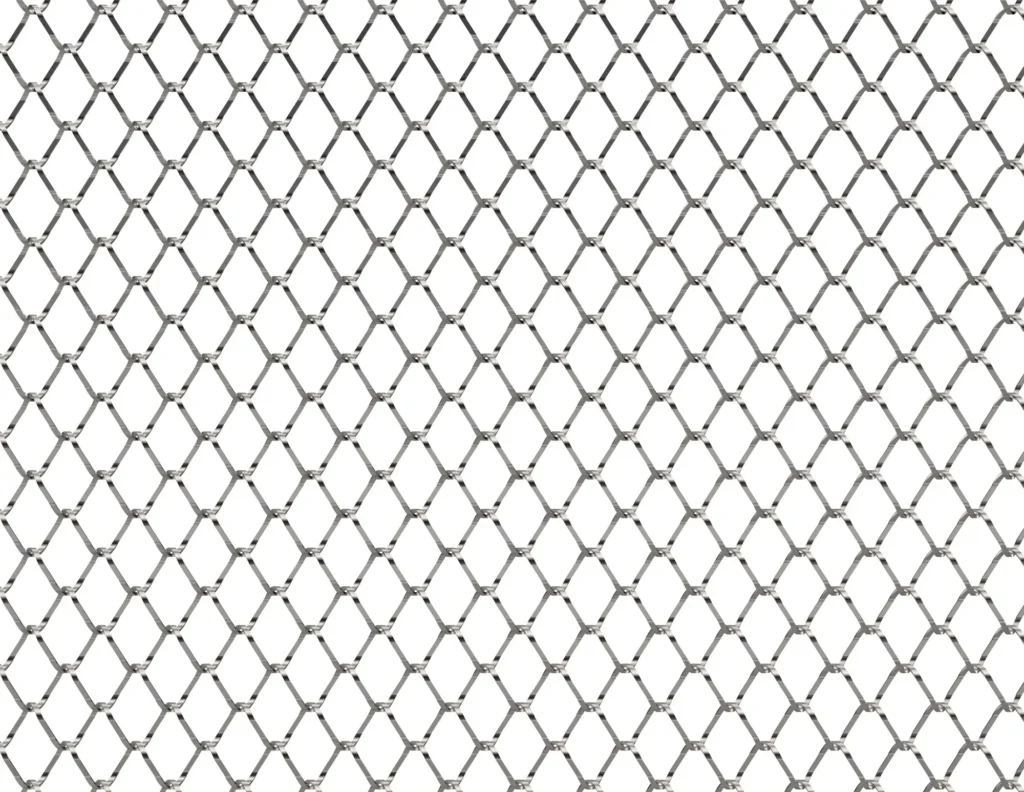

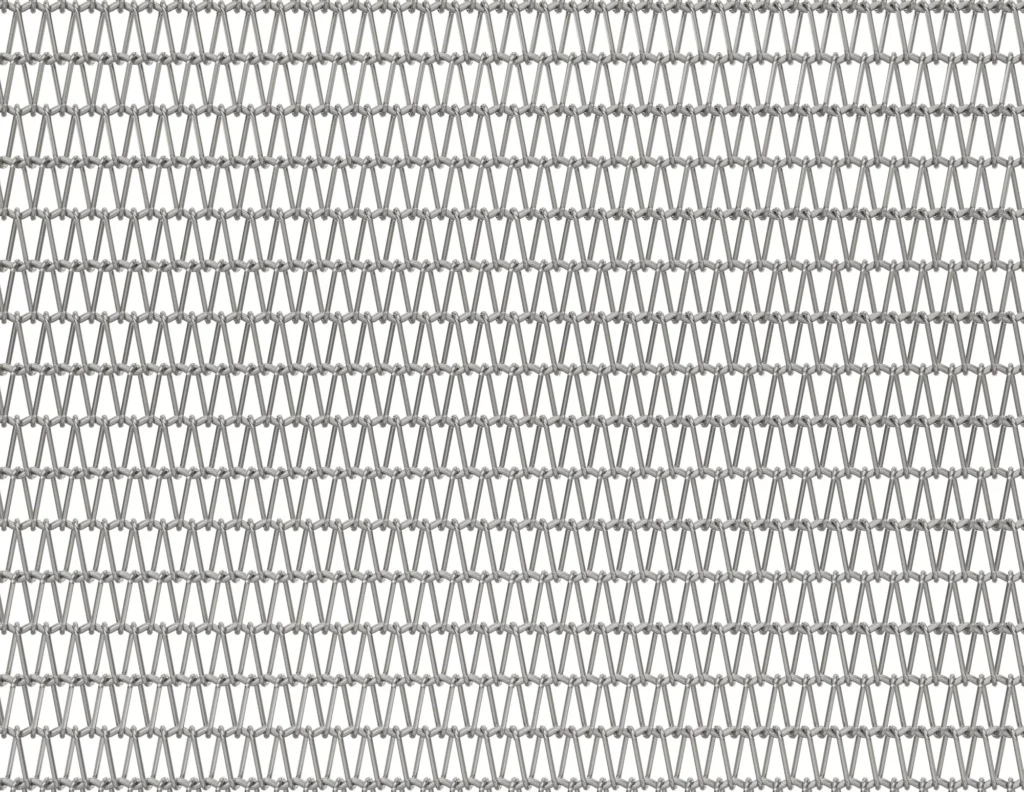

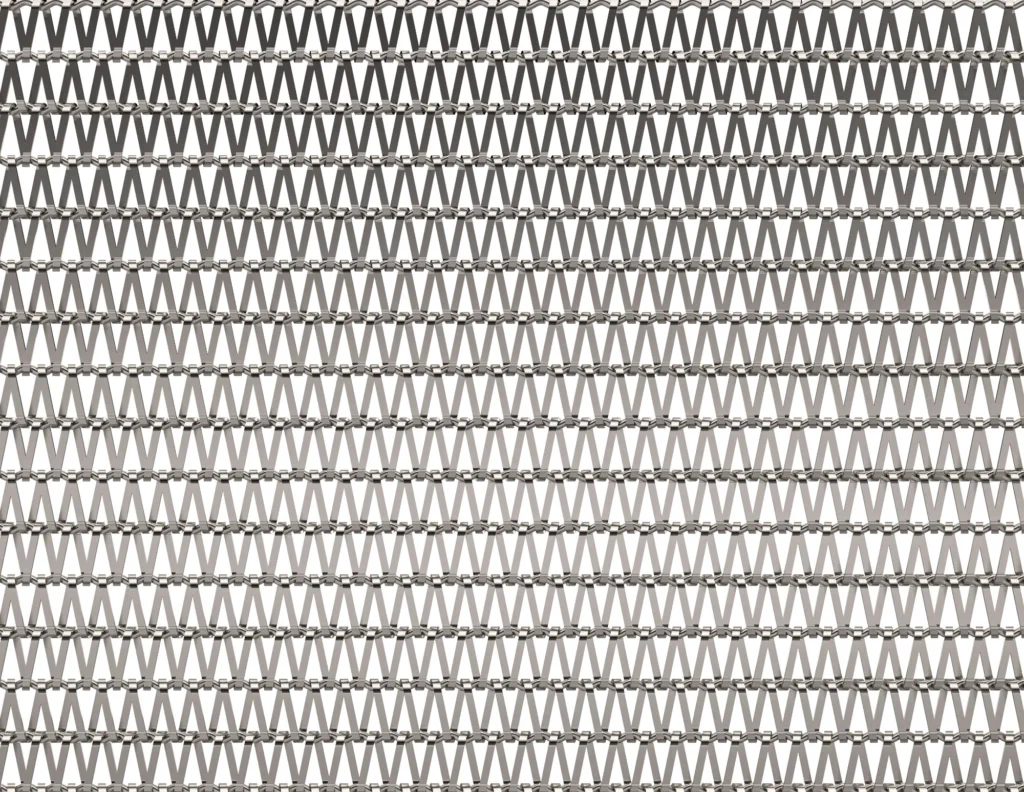

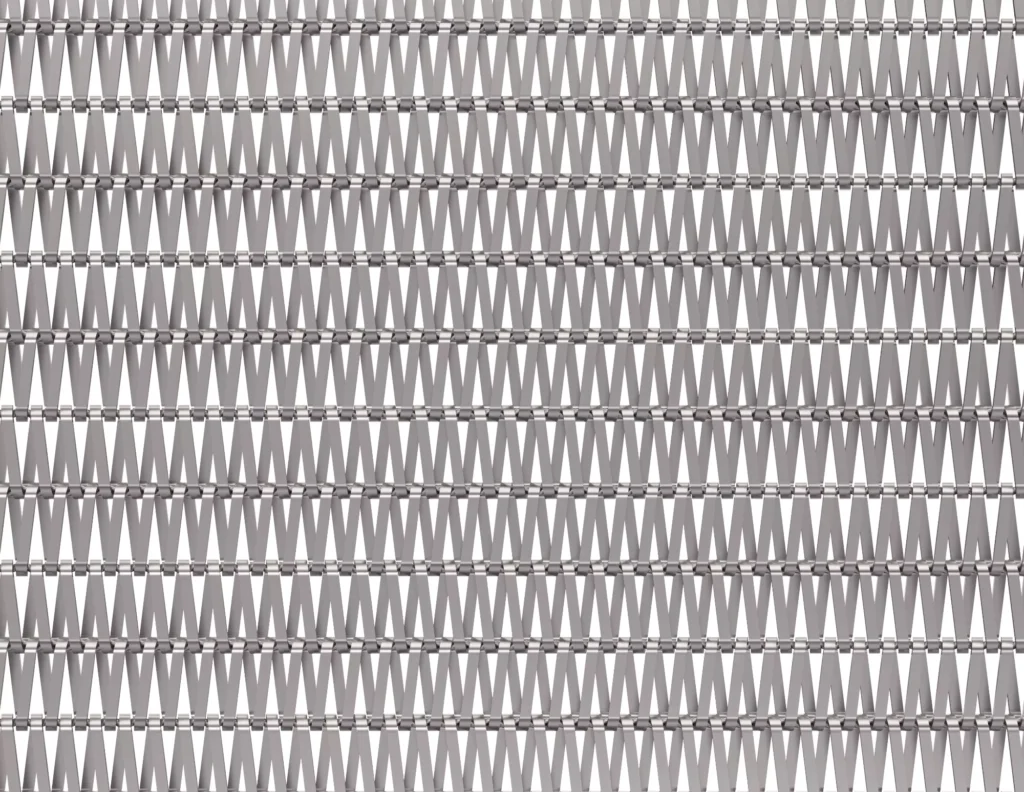

Available models with Stainless Steel Mesh

Discover our collection of stainless steel mesh models, the most versatile option available. All our models are available with this material, offering unparalleled adaptability for various architectural projects. Explore the wide range of options available, ensuring that there’s a perfect mesh for every need.

Projects using our Stainless Steel Mesh

Explore our showcase of projects crafted with stainless steel meshes. Perfect for both interior and exterior applications, stainless steel meshes are the go-to choice for the majority of projects. Their versatility allows for various finishes, including painting and multiple treatments, ensuring suitability for diverse design needs. Discover how stainless steel meshes elevate spaces with their durability, aesthetic appeal, and functional versatility.